The collaboration between Songjiang Shock Absorber Group Co., Ltd. and Changchun Mobile Production Center has brought forth a range of outstanding rubber expansion joint(flanged-rubber-bellows) products. These products have played a significant role as supporting materials for numerous projects of China Mobile, particularly in the Changchun Mobile Production Center Project. Let’s explore the remarkable single sphere rubber expansion joints and their contract details.

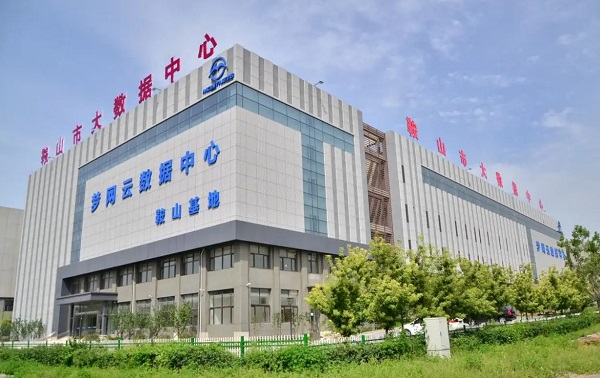

Firstly, let’s provide a brief introduction to the Changchun Mobile Production Center Project. This project, constructed in the Changchun High-tech Industrial Development Zone, is undertaken by China Mobile Communications Group Jilin Co., Ltd. It includes four equipment room buildings, four interconnected office buildings, one dispatch center, and living and auxiliary buildings. With a total construction area of 110,630 square meters and a framework structure, the project is equipped with an underground parking lot. The construction of the Changchun Mobile Production Center Project aims to provide convenient and efficient support for communication infrastructure.

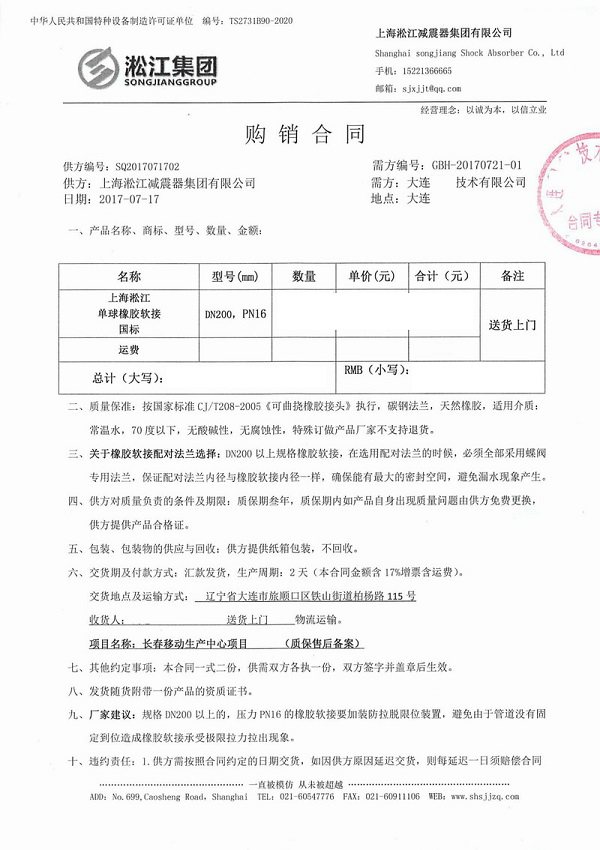

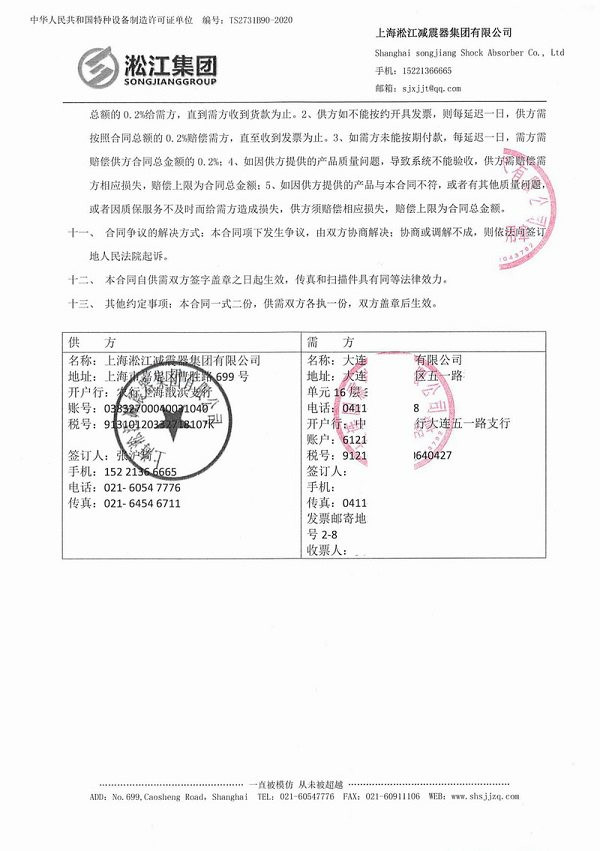

Next, let’s delve into the contract details of the single sphere rubber expansion joints used in the Changchun Mobile Production Center Project. These rubber expansion joints play a crucial role in pipeline systems by significantly reducing vibrations and noise, as well as addressing issues such as interface displacement, axial expansion, and concentricity in pipelines. Depending on the requirements of different media and environments, single sphere rubber expansion joints can be manufactured in various types, including acid-resistant, alkali-resistant, corrosion-resistant, oil-resistant, and heat-resistant variants. They are made from polar rubber materials, ensuring excellent sealing performance. These joints are lightweight, easy to install and maintain, and boast a long service life. It is important to avoid contact with sharp metal instruments during installation to prevent puncturing the sphere. In overhead applications, elastic supports can be used, and the bolts should be tightened diagonally during installation. In cases of high-pressure pipelines, extreme bolts can be utilized to connect the two end flanges. The flange connection standard adheres to the GB4216.3-4216.5 specifications, with additional requirements available. The working pressure levels of these single sphere rubber expansion joints are categorized into 0.6 MPa, 1 MPa, 1.6 MPa, and 2.5 MPa, catering to different needs.

The contract indicates the reciprocal collaborative relationship between these two enterprises.

The authentic photo of songjiang Rubber Expansion Joints purchased by Changchun Mobile Production Center

Through the Changchun Mobile Production Center Project, Songjiang Shock Absorber Group and Changchun Mobile Production Center are jointly striving to provide excellent solutions for communication infrastructure. This collaboration not only showcases Songjiang Shock Absorber Group’s independent research and development capabilities in the field of rubber expansion joints but also makes a significant contribution to the successful implementation of the Changchun Mobile Production Center Project. We look forward to further breakthroughs and innovations arising from this collaboration, bringing more convenience and possibilities to our lives and work.

Related links:[FKM] Expansion joint related welding neck flange “a good helper for pipelines in chemical plants”