In recent years, with the rapid growth of China’s e-commerce industry, JD Group has embarked on an ambitious expansion of its logistics and warehousing facilities nationwide. The successful construction of JD Asia No.1 Logistics Park, located in the Langfang Economic Development Zone, signifies JD Group’s firm foothold in this endeavor. Within the construction of the extensive pipeline systems of this large-scale warehouse facility, the application of flanged rubber bellows produced by Shanghai Songjiang Shock Absorber Group Co., Ltd., equipped with control rods, has emerged as a critical factor in ensuring the efficient operation of the internal drainage and HVAC (Heating, Ventilation, and Air Conditioning) systems. These joints have successfully enhanced the operational efficiency of the large-scale drainage and HVAC systems within JD Asia No.1 Logistics Park, effectively safeguarding the integrity and safety of the pipeline systems within the logistics park.

Adapting to Significant Challenges: Rubber Expansion Joints with Control Rods

The scale of JD Asia No.1 Logistics Park is immense, with a total investment reaching billions of RMB, encompassing warehousing facilities, equipment rooms, and various essential amenities, primarily dedicated to the storage and sorting of high-quality home appliances. To support this vast logistics network, large-scale drainage and HVAC systems serve as indispensable infrastructure components.

However, these pipeline systems face significant challenges during operation. Factors such as temperature fluctuations, vibrations, and large-scale drainage impose stringent requirements on the stability of these systems. It is within this context that Songjiang rubber expansion joints, accompanied by their control rods, have played a pivotal role.

Primary Functions of Control Rods

Precise Positional Control: Control rods enable precise positioning of rubber expansion joints within the pipeline system. This precise control is crucial in ensuring the accurate alignment and fixation of joints, meeting specific engineering requirements.

Absorption of Axial Forces: In large-scale pipeline systems, pipes often bear axial forces stemming from vibrations, temperature fluctuations, and other factors. Control rods effectively absorb and alleviate these forces, thereby maintaining the stability and integrity of the pipeline system.

Prevention of Excessive Deformation: The use of control rods restricts excessive extension or compression of rubber expansion joints, preventing them from exceeding their design limits and enhancing the reliability of the pipeline system.

High Adaptability

The flexible design of Songjiang rubber expansion joints and control rods makes them suitable for various pipeline systems with different diameters and configurations. This high level of adaptability stands as a significant advantage, ensuring the seamless operation of diverse pipeline systems.

The authentic photo of songjiang rubber expansion joints for JD Asia No.1 Logistics Park Pipeline Systems.

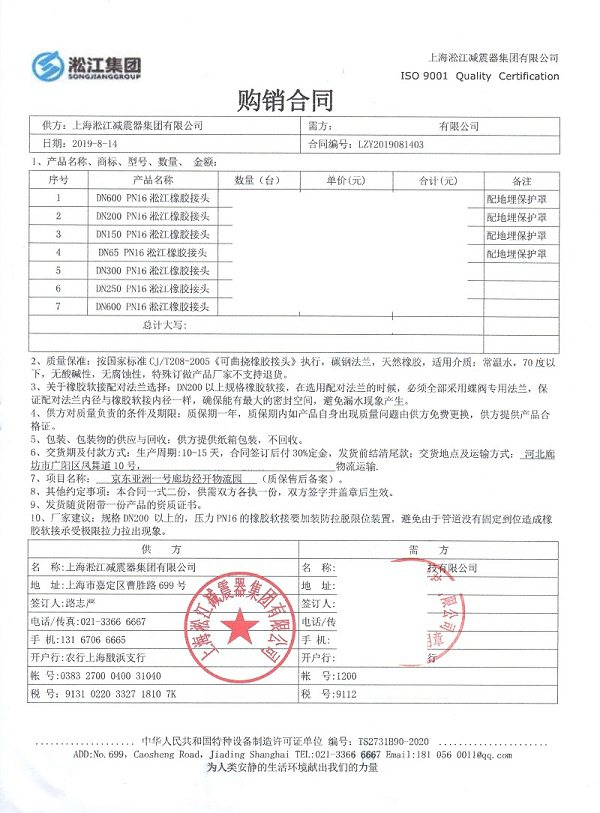

The contract indicates the reciprocal collaborative relationship between these two enterprises.

The application of Songjiang rubber expansion joints with control rods has provided essential foundational support for the efficient operation of the drainage and HVAC systems within JD Asia No.1 Logistics Park. Their capabilities in precise positional control, absorption of axial forces, and prevention of excessive deformation guarantee the efficient operation and long-term reliability of the pipeline systems. The engineering solutions offered by Songjiang have played a vital role in supporting large-scale projects, making a significant contribution to the successful operation of JD Asia No.1 Logistics Park.

Related links:[NR] Expansion joint related welding neck flange “TS pressure pipe production license enterprise”