Shanghai Songjiang Group is proud to highlight the successful implementation of its flanged rubber bellows at Kaizhou Cement Factory. Located in Kaixian, Kaizhou Cement Factory has been a prominent player in the region’s industrial sector since its establishment in 2008. With a production capacity of 1.5 million tons of cement annually, the factory needed a reliable solution for managing the challenges associated with industrial wastewater treatment. Partnering with Shanghai Songjiang Group, they integrated Songjiang’s flanged rubber bellows into their systems, significantly enhancing their operational efficiency.

The cement production process involves various stages that generate industrial wastewater. Effective management of this wastewater is crucial to maintaining environmental compliance and operational efficiency. Songjiang flanged rubber bellows, known for their flexibility and durability, were chosen to address these needs.

Advantages of Songjiang Flanged Rubber Bellows in Industrial Wastewater Treatment:

Exceptional Flexibility and Adaptability:

Songjiang flanged rubber bellows are designed to accommodate the thermal expansion and contraction that occurs in pipelines due to temperature fluctuations. This flexibility ensures that the pipelines remain intact and functional, preventing leaks and ruptures that could disrupt wastewater treatment processes.

Vibration Isolation:

Industrial machinery used in cement production generates significant vibrations, which can compromise the integrity of pipeline systems. The flanged rubber bellows from Songjiang effectively dampen these vibrations, protecting the pipelines from damage and reducing noise pollution. This is particularly important in maintaining a stable and safe working environment.

Leak Prevention:

A leak-free system is essential for the efficient treatment of industrial wastewater. Songjiang flanged rubber bellows provide secure and tight connections, even under varying pressure conditions. This reliability is crucial in preventing the escape of potentially harmful substances, ensuring that the wastewater treatment process runs smoothly and efficiently.

Ease of Installation and Maintenance:

The inherent flexibility of Songjiang’s flanged rubber bellows allows them to compensate for any misalignments that may occur during installation. This ease of installation minimizes downtime and ensures that the wastewater treatment system is up and running quickly. Additionally, the durability of these bellows reduces the frequency of maintenance, resulting in lower operational costs over time.

Corrosion Resistance:

The materials used in the construction of Songjiang flanged rubber bellows are highly resistant to corrosion, which is a common issue in wastewater treatment due to the presence of various chemicals. This resistance extends the lifespan of the bellows, ensuring long-term reliability and performance even in harsh conditions.

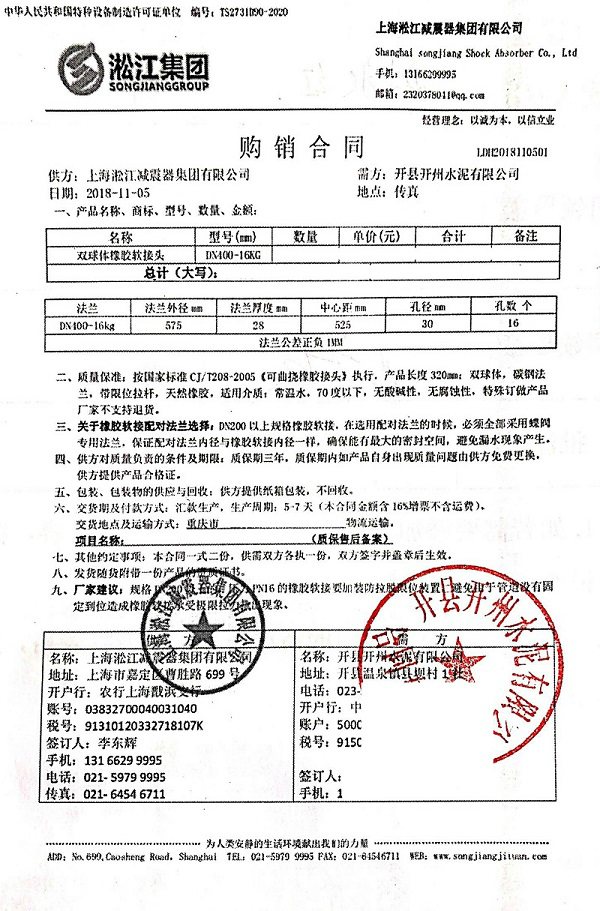

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Contribution to Kaizhou Cement Factory’s Operations

The integration of Songjiang flanged rubber bellows has significantly improved the efficiency and reliability of Kaizhou Cement Factory’s industrial wastewater treatment system. By addressing the challenges of thermal expansion, vibration, and potential leaks, these bellows have played a crucial role in maintaining the operational integrity of the factory’s wastewater management processes. This collaboration has not only enhanced the factory’s compliance with environmental regulations but also contributed to a safer and more efficient production environment.

Related links:[NR] Double ball expansion joint related welding neck flange“Shockproof and noise reduction”