In the intricate landscape of automotive manufacturing, efficiency and reliability are paramount. The incorporation of Songjiang Flanged Rubber Bellows at SAIC-GM-Wuling Liuzhou Factory embodies the seamless integration of innovative solutions aimed at optimizing production processes.

At SAIC-GM-Wuling Liuzhou Factory, Songjiang Flanged Rubber Bellows play a pivotal role in ensuring the smooth operation of various systems within the manufacturing facility. These bellows offer crucial flexibility and adaptability, addressing the dynamic requirements of automotive production.

A primary application of Songjiang Flanged Rubber Bellows lies in their integration within the factory’s piping systems. These bellows efficiently absorb vibrations and shocks, preserving the integrity of the piping infrastructure. By accommodating thermal expansion and contraction, they prevent damage and sustain the efficiency of fluid and gas flow throughout the production line.

Furthermore, Songjiang Flanged Rubber Bellows contribute significantly to the alignment and stability of piping connections. In the complex milieu of automotive manufacturing, precision is paramount. These bellows compensate for misalignments and offsets, ensuring secure and leak-free connections between pipes and equipment.

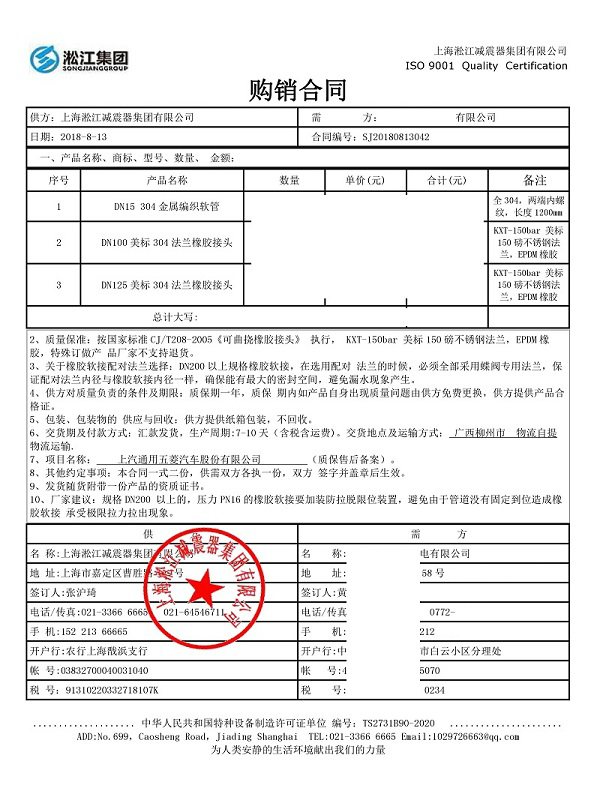

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Beyond enhancing operational efficiency, Songjiang Flanged Rubber Bellows facilitate maintenance activities within the factory. Their easy installation and accessibility streamline repair and replacement procedures, minimizing downtime and maximizing productivity.

Related links:[FKM] Expansion joint related welding neck flange “a good helper for pipelines in chemical plants”