Shanghai Songjiang Vibration Isolator Group Co., Ltd. has long been a leader in the field of vibration isolation and flexible connection products such as flanged rubber bellows,spring vibration isolators and metal hoses,etc. Renowned for its innovation, quality, and reliability, Songjiang has consistently provided top-tier solutions for a wide range of industries. Among its flagship products are the flanged rubber bellows, which have been pivotal in numerous high-profile projects worldwide, showcasing the company’s commitment to excellence and technological advancement.

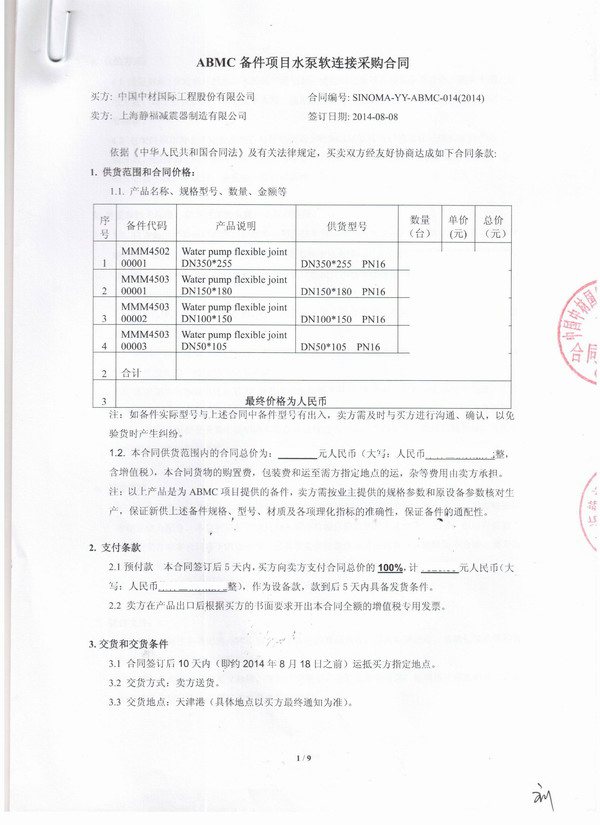

In the CNBM International ABMC 10,000 Tons Per Day Cement Production Line Project, Shanghai Songjiang’s expertise and superior products played an indispensable role. This project, developed by Abu Dhabi’s ARKAN Building Materials Group and executed as an EPC turnkey project by CNBM International Overseas Business Development Company, required the highest standards of quality and durability in its components. Shanghai Songjiang was chosen to supply the crucial DN250 single rubber expansion joints, highlighting the trust placed in their products for such a significant undertaking.

Project Overview

The ABMC cement production line project, with a contract value of $276,313,000, began construction on September 16, 2007. By September 2009, the equipment installation was completed, followed by single equipment commissioning in October 2009. The material crushing and pre-homogenization sub-item feeding commissioning started in April 2011. The plant was successfully ignited on November 7, 2012, and clinker production commenced on November 12. Throughout this period, Shanghai Songjiang’s DN250 single rubber expansion joints were integral to the project’s success, ensuring seamless operation and reliability.

Advantages of DN250 Flanged rubber bellows

Shanghai Songjiang’s DN250 flanged rubber bellows are known for their robust construction and exceptional performance. Here are the key benefits they provided to the ABMC cement production line project:

Vibration and Noise Reduction: The joints significantly reduce vibration and noise, ensuring a quieter and more stable operation environment.

Flexibility and Convenience: With their compact size, lightweight, and excellent elasticity, these joints are easy to install and maintain, contributing to the project’s overall efficiency.

Accommodating Displacement: They can handle lateral, axial, and angular displacement, making them ideal for pipelines with misalignment or non-parallel flanges, thus enhancing the flexibility of the installation.

Enhanced Performance: The joints reduce structural noise transmission and provide strong vibration absorption, crucial for maintaining optimal operational performance.

Wide Range of Applications: Their excellent performance makes them suitable for various industries, including chemical, construction, water supply, drainage, petroleum, light and heavy industries, refrigeration, sanitation, plumbing, fire protection, and power. They are particularly effective in pipelines with significant vibration and frequent thermal changes.

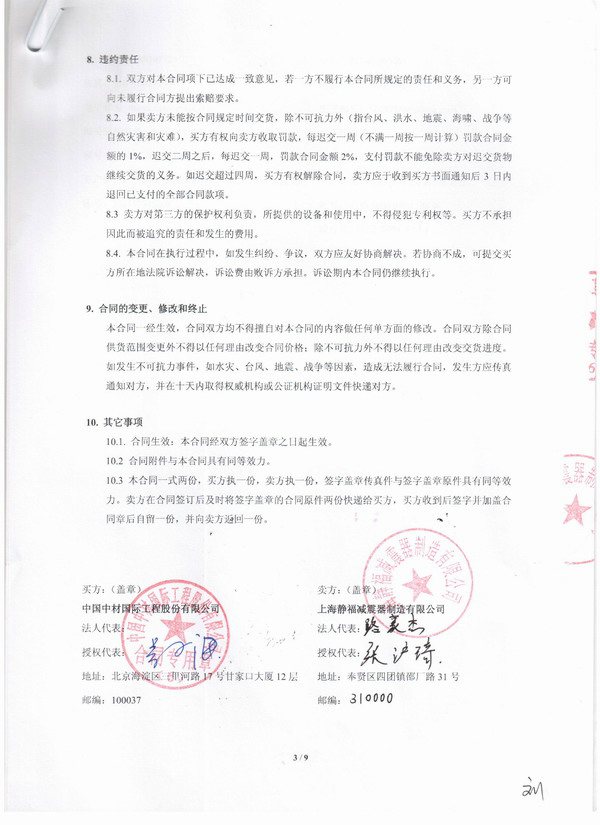

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion,Shanghai Songjiang’s DN250 flanged rubber bellows proved to be a critical component in the CNBM International ABMC 10,000 Tons Per Day Cement Production Line Project. Their superior quality and performance ensured the project’s smooth execution and long-term reliability. This case study exemplifies the importance of choosing high-quality components and highlights Shanghai Songjiang’s role as a trusted provider of advanced industrial solutions.

Related links:[NR] Expansion joint related welding neck flange “TS pressure pipe production license enterprise”