Rubber Expansion joints play a vital role in waste water treatment systems, bringing numerous key advantages to waste water pumping systems. The excellent collaboration between Wuhan Tianma Microelectronics Co., Ltd. and Shanghai Songjiang Shock Absorber Group Co., Ltd. has resulted in the specialized and customized Songjiang flanged rubber bellows demonstrating outstanding performance in compensating for displacement and absorbing vibrations, providing exceptional assurance for system operations.

The waste water pumping system is a critical component that pumps waste water from sewage collection tanks or sewers and transports it to treatment facilities for further processing. During this process, rubber joints tightly connect the water pump to the pipeline system. Through their flexible characteristics, rubber joints effectively absorb the vibrations generated by the water pump operation, reducing the transmission of vibrations to the pipelines and equipment, thus lowering the overall vibration levels and mitigating adverse effects on the pipelines and equipment.

Moreover, due to factors such as temperature fluctuations, changes in water pressure, and equipment operation, minor displacements and deformations may occur between the water pump and pipelines. The specially customized Songjiang rubber joints possess remarkable flexibility and deflection capability, allowing them to adapt to these displacements and ensuring the stability and integrity of the pipeline system.

The authentic photo of songjiang rubber expansion joints for Waste Water Pumping Systems

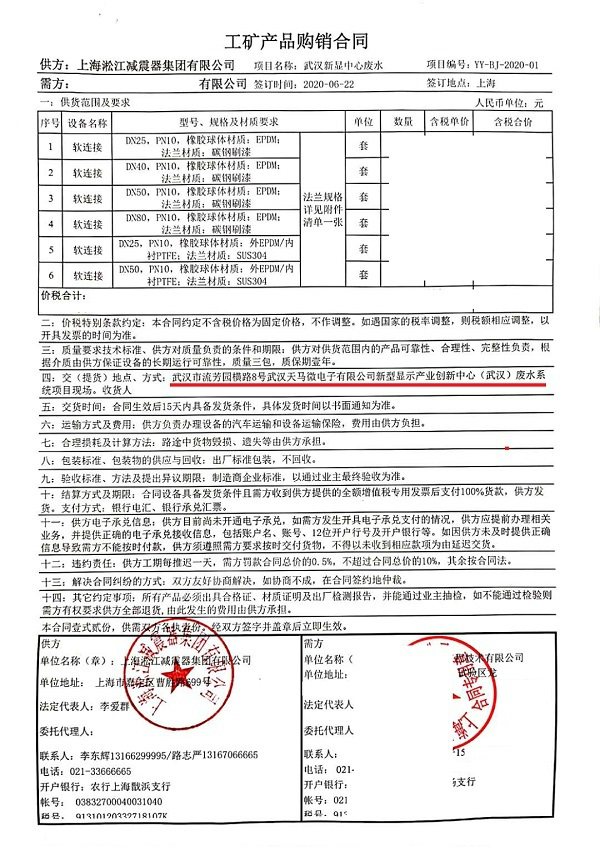

The contract indicates the reciprocal collaborative relationship between these two enterprises.

Through meticulous customization by Shanghai Songjiang Shock Absorber Group Co., Ltd., the customized rubber joints provided to Wuhan Tianma have exhibited exceptional performance in the waste water pumping system. They not only excel in vibration absorption and compensating for displacement but also demonstrate remarkable capabilities in preventing leakage and reducing noise. This collaboration has significantly improved the efficiency and stability of the waste water treatment system, contributing to environmental protection and sustainable development. The close cooperation between Wuhan Tianma and Songjiang rubber joints paves the way for a brighter future for waste water pumping systems.

Related links:[SUS] Expansion joint related welding neck flange “edible grade test report”