In the bustling realm of food processing, operational efficiency and product quality are paramount. Qingdao Yinleduo Food Processing Factory, a leading player in the industry, recognized the importance of mitigating machinery vibrations to ensure seamless operations and product integrity. Collaborating with Shanghai Songjiang Vibration Absorber Group Co., Ltd.which is adept at manufacturing flanged rubber bellows and spring vibration isolators, Yinleduo implemented innovative solutions tailored to their specific needs, with remarkable results.

Enhanced Machinery Performance:

Yinleduo’s production lines rely on heavy machinery, including mixers, grinders, and packaging equipment. However, vibrations generated by these machines often posed challenges, leading to decreased efficiency and increased maintenance requirements. By integrating Shanghai Songjiang’s Spring Vibration Isolators, Yinleduo effectively minimized vibrations, optimizing machinery performance and ensuring consistent product quality. The isolators’ ability to absorb vibrations proved instrumental in reducing wear and tear on equipment, resulting in fewer breakdowns and enhanced productivity.

Maintaining Hygienic Standards:

In food processing facilities, maintaining hygienic standards is paramount to ensuring food safety. Vibrations from machinery can disrupt production processes and compromise hygiene. Shanghai Songjiang’s isolators not only reduced vibrations but also contributed to a cleaner working environment. With smoother operations and reduced equipment movement, Yinleduo could uphold stringent hygiene standards, safeguarding the integrity of their products and meeting regulatory requirements with ease.

Ensuring Employee Wellbeing:

A harmonious work environment is essential for employee morale and productivity. Excessive machinery vibrations not only disrupt operations but also pose risks to employee wellbeing. By implementing Shanghai Songjiang’s isolators, Yinleduo created a more comfortable and safe workplace environment. Reduced noise levels and minimized vibrations led to improved working conditions, enhancing employee satisfaction and motivation.

Sustainable Operational Practices:

In today’s environmentally conscious landscape, sustainability is a key focus for businesses across industries. Shanghai Songjiang’s isolators not only improved operational efficiency but also aligned with Yinleduo’s commitment to sustainability. By reducing energy consumption and minimizing machinery wear, the isolators supported Yinleduo in their journey towards sustainable manufacturing practices, reducing their environmental footprint while optimizing operations.

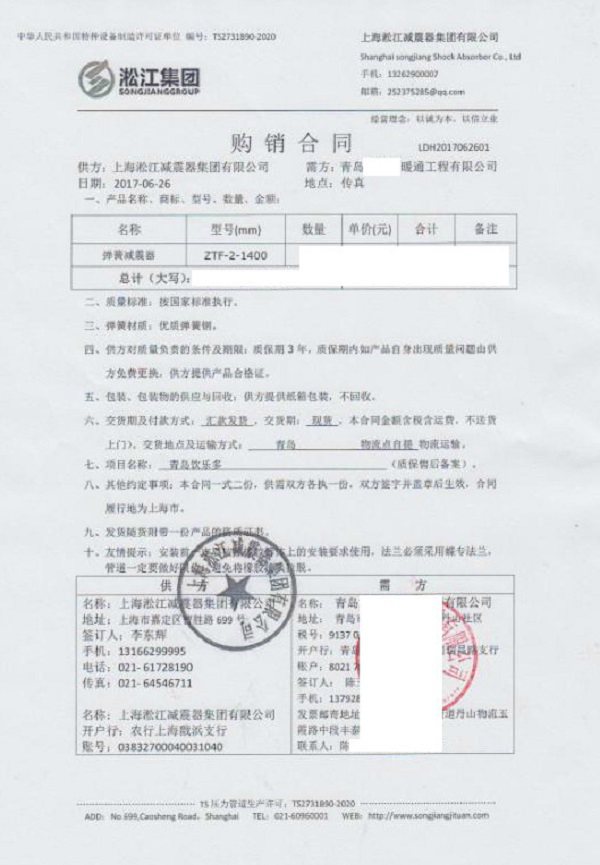

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, the successful application of Shanghai Songjiang’s Spring Vibration Isolators at Qingdao Yinleduo Food Processing Factory exemplifies the transformative impact of innovative solutions tailored to meet specific industry needs. Through collaboration and a shared commitment to excellence, Yinleduo has achieved significant improvements in operational efficiency, product quality, and employee satisfaction, setting a benchmark for excellence in the food processing industry.

Related links:ZTF type damping spring vibration isolator for chiller