Renowned for its innovation and dedication to excellence, Nanjing Changan Mazda Automotive Factory continues to enhance its production processes to meet the demands of the automotive industry. As part of this commitment, the factory has opted to incorporate Songjiang Flanged Rubber Bellows into its infrastructure. This article provides a comprehensive overview of the installation and application specifics of these bellows within the factory’s operations.

Nanjing Changan Mazda Automotive Factory, a cornerstone of automotive manufacturing, prioritizes efficiency and reliability in its production processes. Recognizing the significance of flexible and resilient pipeline systems, the factory has selected Songjiang Flanged Rubber Bellows for integration into various critical areas of its operations.

The installation process commences with a thorough evaluation of the factory’s pipeline network, identifying key locations where flexibility and vibration attenuation are essential. Songjiang Flanged Rubber Bellows are strategically installed within pivotal sections such as the stamping, welding, painting, and final assembly workshops, where dynamic movements and temperature fluctuations are prevalent.

Each bellows undergoes stringent testing to ensure compliance with industry standards and its ability to withstand the rigorous conditions of automotive manufacturing. Installation teams meticulously adjust the bellows to ensure seamless integration and optimal performance within the existing infrastructure of the factory.

Following the completion of installation, the benefits of Songjiang Flanged Rubber Bellows become immediately apparent. They effectively dampen vibrations, prevent pipeline ruptures, and compensate for thermal expansion and contraction, thereby enhancing operational efficiency and reliability.

As operations persist at Nanjing Changan Mazda Automotive Factory, the integration of Songjiang Flanged Rubber Bellows proves instrumental in maintaining a streamlined and uninterrupted production process. Their adaptability and durability significantly contribute to the factory’s ability to deliver top-tier vehicles to the market.

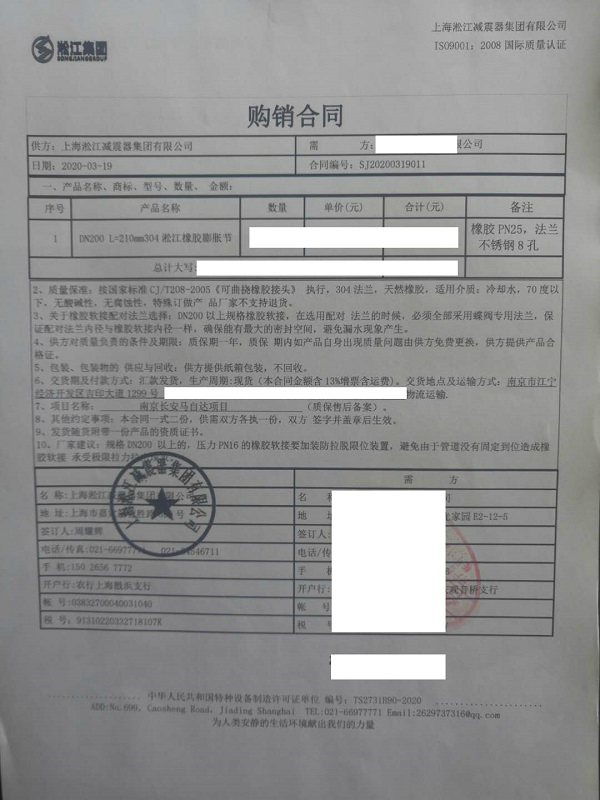

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, the installation and application of Songjiang Flanged Rubber Bellows at Nanjing Changan Mazda Automotive Factory underscore the factory’s commitment to innovation and excellence. By optimizing pipeline systems and bolstering operational efficiency, these bellows play a pivotal role in sustaining the factory’s competitive edge in the automotive industry.

Related links:[Galvanized] Expansion joint related welding neck flange “export standard”