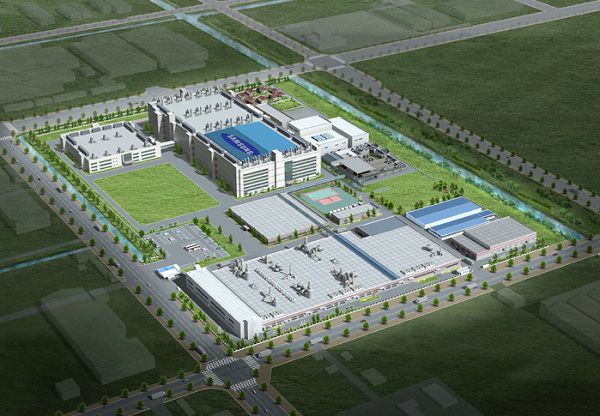

Songjiangflex, a trailblazer in the realm of flanged rubber bellows, introduces a fusion of innovation, reliability, and efficiency to a wide array of projects. Our state-of-the-art flanged rubber bellow products, celebrated for their exceptional attributes, play a pivotal role in enhancing various industrial applications. In this article, we delve into Songjiang’s impressive flanged rubber bellow offerings and their remarkable contributions to the Saudi Yanbu Seawater Desalination Project.

Elevating Engineering Excellence: A Crucial Collaboration

The Saudi Yanbu Seawater Desalination Project is a monumental undertaking that necessitates the highest standards of performance and durability. Songjiang’s flanged rubber bellows prove to be a perfect match for this challenging project, offering a broad range of advantages:

Economic Efficiency: In contrast to mechanical expansion and filler cushioning, our flanged rubber bellows are compact, lightweight, easily installed, and cost-effective. They reduce labor requirements, and their smooth interior minimizes fluid resistance, preserving the integrity of pipe systems. Furthermore, their wide temperature range ensures functionality even in high-temperature conditions.

Flexibility and Adaptability: These flanged rubber bellow products exhibit exceptional elasticity, accommodating compression, extension, torsion, and vertical displacement. They safeguard pipe systems against damage resulting from thermal expansion, contraction, or uneven foundation settling.

Vibration Dampening and Noise Reduction: Featuring a rubber dampening sphere, our flanged rubber bellows effectively mitigate vibrations, reduce mechanical noise, and absorb fluid impact sounds. Proper installation between vibrating machinery and metal pipes further diminishes structural noise transmission.

Pressure Resistance: With a multi-layered spherical structure, our flanged rubber bellows excel in withstanding internal pressure. They demonstrate robust resistance to explosions and external impacts, retaining their shape under pressure. Available for various working pressures, including 0.6MPa, 1.0MPa, and 1.6MPa.

Resilience: Even when compressed under force, our flanged rubber bellows swiftly return to their original state once external pressure is removed.

Installation Insights: Perfecting Seawater Desalination

In the context of the Saudi Yanbu Seawater Desalination Project, the installation of flanged rubber bellows deserves special attention. To ensure optimal performance and longevity, proper alignment, secure bolting, and regular maintenance are essential. These bellows should be installed with precision, avoiding over-tightening or misalignment, which could compromise their effectiveness.

The authentic photo of songjiang rubber expansion joints for Seawater Desalination

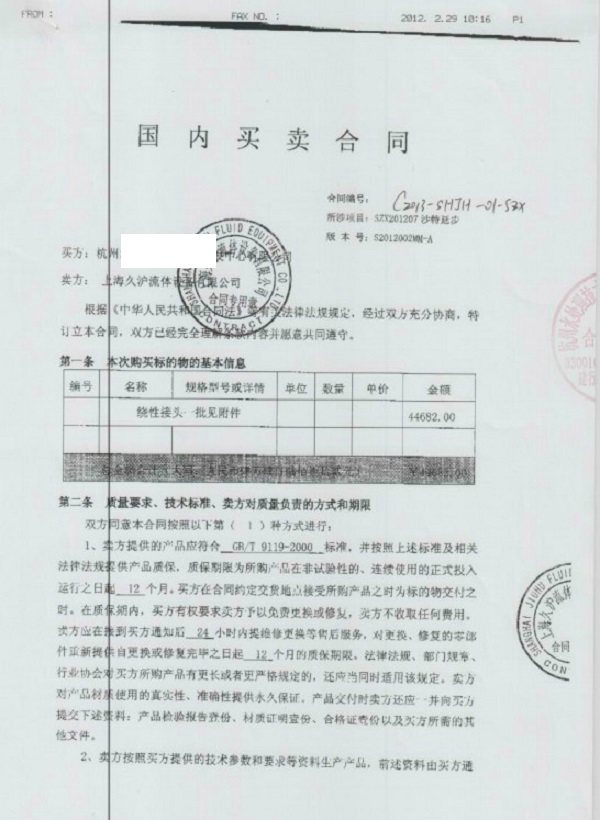

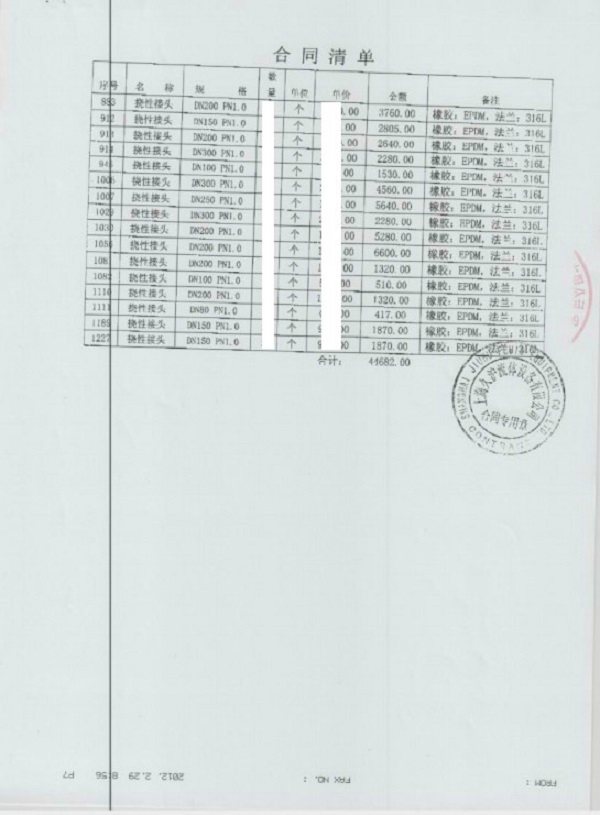

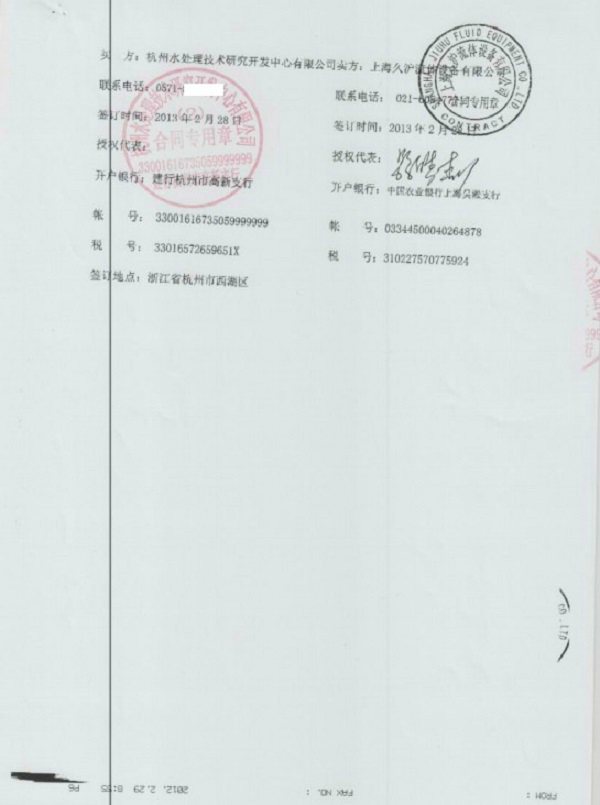

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

A Vision of the Future

The collaboration between Songjiang and the Saudi Yanbu Seawater Desalination Project exemplifies a commitment to cutting-edge technology, sustainability, and a promising future. By delivering top-tier flanged rubber bellows, Songjiang contributes to setting new industry standards. Our products optimize efficiency and durability in demanding projects, ensuring long-term success.

Related links:[SUS] Expansion joint related welding neck flange “edible grade test report”