In the realm of industrial manufacturing, operational resilience is paramount for sustained success amidst dynamic challenges. This case study delves into the collaborative journey between Hangzhou Pepsi Beverage Factory and Flanged Rubber Bellows, illuminating their concerted efforts in optimizing operational efficiency and safety.

Introduction:

Established on December 8, 2005, Hangzhou Pepsi Beverage Factory stands as a beacon of quality and innovation in the beverage industry. Led by legal representative Feng Xiaoming, the factory specializes in producing the renowned Pepsi Cola series beverages, among other products. As a subsidiary of PepsiCo, Inc., the factory operates within a vast global network, epitomizing excellence in manufacturing.

Challenges Faced:

Hangzhou Pepsi Beverage Factory encountered challenges in maintaining the integrity and efficiency of its piping systems amidst rigorous production demands. Factors such as corrosive substances, temperature fluctuations, and mechanical stresses posed significant hurdles to operational efficiency. In addressing these challenges, the factory sought a strategic partnership with a trusted industry leader.

Solution Implemented:

In response to the factory’s exigencies, a collaborative partnership was forged with Flanged Rubber Bellows, renowned for its expertise in providing durable and resilient piping solutions. Leveraging high-quality flanged rubber bellows, the partners aimed to fortify the factory’s piping infrastructure against corrosion, thermal fluctuations, and mechanical vibrations.

Implementation Process:

The implementation process commenced with a comprehensive assessment of the factory’s existing piping systems, identifying critical stress points and operational requirements. Guided by precision and reliability, Flanged Rubber Bellows tailored a solution bespoke to the factory’s needs. Through meticulous installation and integration processes, the rubber bellows were seamlessly incorporated into the factory’s piping network, ensuring enhanced durability and operational resilience.

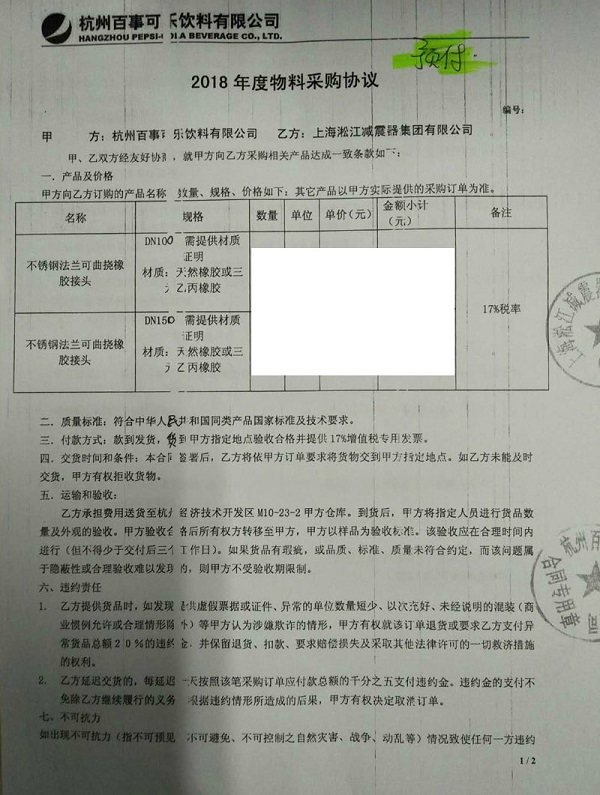

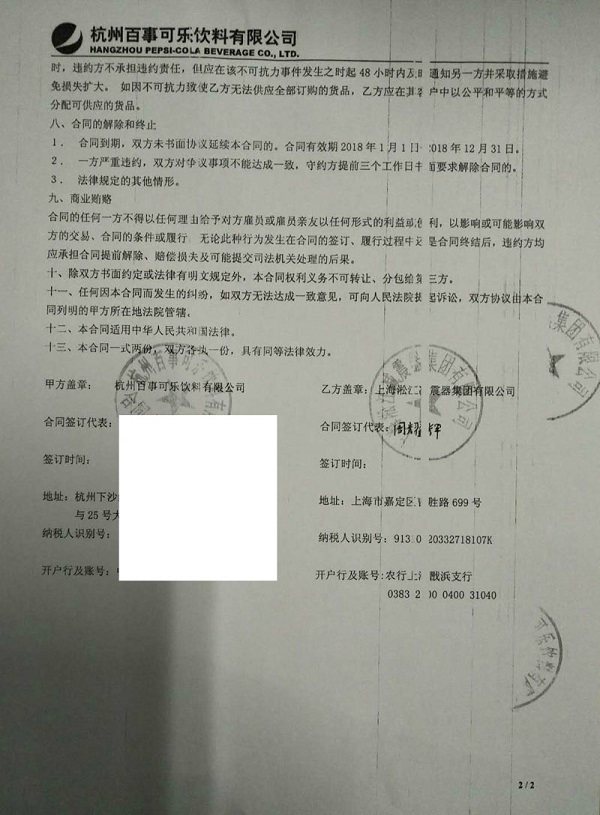

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Results Achieved:

The integration of Flanged Rubber Bellows yielded transformative results for Hangzhou Pepsi Beverage Factory. By bolstering the flexibility and resilience of the piping systems, the rubber bellows effectively mitigated operational vibrations, thermal stresses, and corrosive agents. This proactive approach not only optimized operational efficiency but also minimized downtime and maintenance costs, enhancing the factory’s overall competitiveness and sustainability.

Related links:[SUS] Expansion joint related welding neck flange “edible grade test report”