Shanghai Songjiang Vibration Absorber Group Co., Ltd. has established itself as a leader in the automotive industry, renowned for its commitment to excellence and innovative product solutions. With a diverse portfolio of high-quality products, Songjiang has continuously exceeded customer expectations. Among its top-selling products is the Songjiang Flanged Rubber Bellows, designed to provide superior flexibility and durability in various industrial applications.

Case Study: Installation and Application of Songjiang Flanged Rubber Bellows at Wuhan Shenlong Automobile Plant

In a recent collaboration, Songjiang Flanged Rubber Bellows were installed at the Wuhan Shenlong Automobile Plant, a subsidiary of Great Wall Motors. These bellows, crafted with precision using stainless steel flanges and premium-grade rubber, were seamlessly integrated into the plant’s manufacturing processes. With their ability to withstand high pressures and accommodate thermal expansion and contraction, Songjiang’s flanged rubber bellows proved indispensable in ensuring the smooth operation of critical equipment.

The implementation of Songjiang Flanged Rubber Bellows at Wuhan Shenlong Automobile Plant has significantly enhanced production efficiency and reliability. By effectively absorbing vibrations and compensating for misalignments, the bellows have minimized downtime and maintenance costs, thereby optimizing overall operational performance. As a result, the plant has been able to meet production targets more efficiently and maintain its competitive edge in the automotive market.

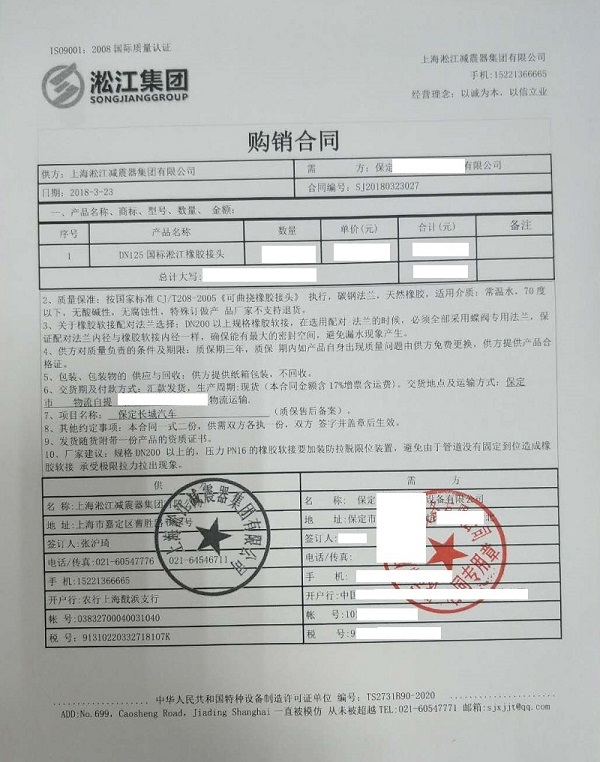

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, the successful application of Songjiang Flanged Rubber Bellows at Wuhan Shenlong Automobile Plant underscores Songjiang’s unwavering commitment to innovation and customer satisfaction. With a steadfast dedication to quality and collaboration, Songjiang continues to play a pivotal role in driving efficiency and excellenc e across various industries. As a trusted partner, Songjiang remains poised to deliver cutting-edge solutions that meet the evolving needs of its customers, reaffirming its status as a leader in the global market.

Related links:[NBR] Expansion joint related welding neck flange “automatic production process”