Suzhou Bosch Automotive Components stands as a beacon of innovation and reliability in the automotive manufacturing realm. Renowned for its commitment to quality and cutting-edge solutions, Suzhou Bosch has continually pushed the boundaries of automotive engineering. In this case study, we explore the seamless integration of Shanghai Songjiang Group which specializes in manufacturing flanged rubber bellows and spring vibration isolators into Suzhou Bosch’s automotive systems, showcasing its transformative impact on performance and durability.

Suzhou Bosch Automotive Components: A Legacy of Excellence

Established in 1999, Suzhou Bosch Automotive Components has emerged as a key player in the automotive components industry. With a steadfast focus on innovation and customer satisfaction, Suzhou Bosch has garnered acclaim for its diverse product portfolio and unwavering commitment to quality. Accredited with TS 16949 quality system certification and recognized as a high-tech enterprise, Suzhou Bosch epitomizes precision engineering and technological prowess.

Metal Bellows: Revolutionizing Automotive Systems

Metal Bellows, revered for their versatility and reliability, have revolutionized automotive manufacturing. Serving as adept compensators, Metal Bellows adeptly counter temperature and pressure differentials within vehicle systems, ensuring optimal performance and longevity. Moreover, their ability to absorb vibrations and reduce noise transmission enhances passenger comfort and vehicle durability. Metal Bellows also excel in compensating for axial and radial displacements, safeguarding against structural damage and optimizing system integrity.

Case Study: Suzhou Bosch’s Integration of Metal Bellows

Suzhou Bosch Automotive Components has seamlessly integrated Metal Bellows into its automotive systems, ushering in a new era of performance and reliability. In the chassis control system, Metal Bellows effectively compensate for temperature-induced expansions, ensuring precise alignment and superior handling dynamics. Furthermore, in the exhaust system, Metal Bellows mitigate vibrations and minimize noise transmission, resulting in a smoother and quieter driving experience.

Within the powertrain system, Metal Bellows facilitate seamless torque transmission while mitigating axial and radial displacements, optimizing power delivery and minimizing drivetrain wear. Additionally, in fluid transmission systems, Metal Bellows serve as reliable seals, preventing leakage and enhancing fluid transfer efficiency between components.

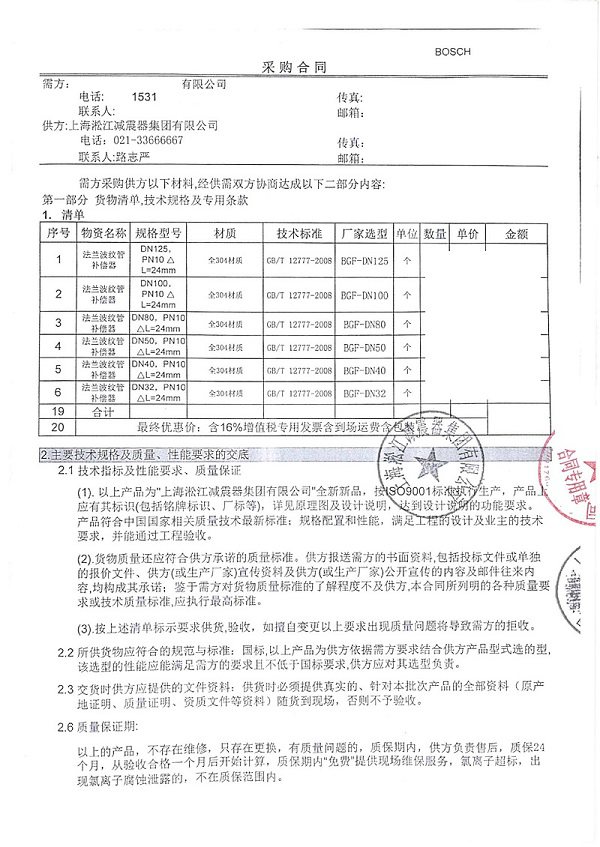

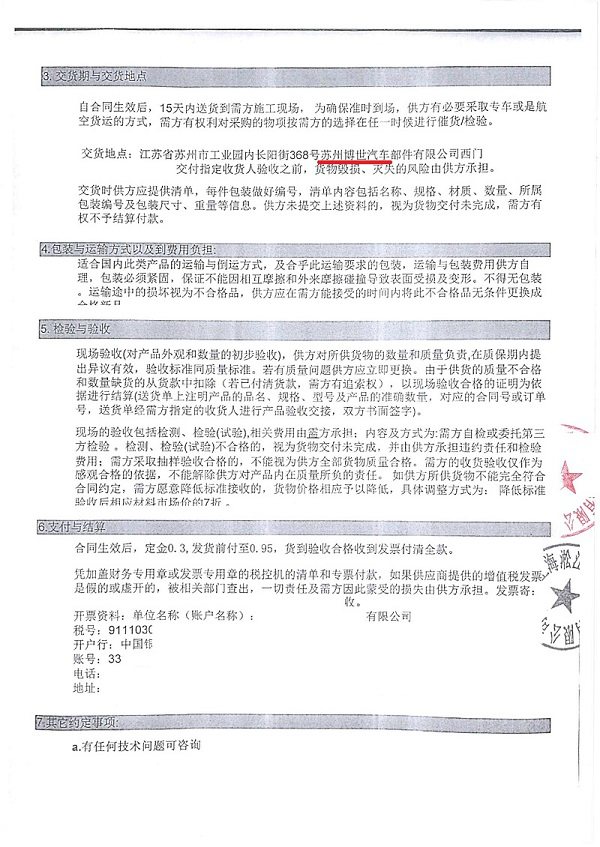

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

The successful integration of Metal Bellows into Suzhou Bosch Automotive Components underscores the symbiotic relationship between innovation and engineering excellence. By harnessing the diverse capabilities of Metal Bellows, Suzhou Bosch has achieved unparalleled performance, reliability, and comfort in its automotive systems. As automotive technology continues to evolve, Metal Bellows remain indispensable components, driving advancements in vehicle performance and user satisfaction.

Related links:BGF Metallic Expansion Joint