Shanghai Songjiang Vibration Absorber Group Co., Ltd. Official Website presents: Contract details for single rubber expansion joints supplied to Dongfang Hope Chongqing Cement Plant for Yangtze River water intake. The Songjiang Group offers rubber expansion joint products to numerous cement plants. The following is a description of the single rubber expansion joint for the Yangtze River water intake pipeline at the cement plant, with a length of 5 meters and pressure rating of 25kg.

Introduction to Dongfang Hope Chongqing Cement Plant:

Dongfang Hope Chongqing Cement Co., Ltd. is a large-scale building materials enterprise solely invested by Dongfang Hope Group, with a registered capital of 300 million yuan and a total planned investment of 3 billion yuan. Located in Zhanpu Town, Fengdu County, Chongqing City, it was established in April 2009 and was one of the key projects of Chongqing Municipal Government in 2009. Covering an area of over 1,500 acres, the company adopts internationally advanced external decomposition new dry process cement production technology. After completion in three phases, it will achieve an annual production capacity of over 12 million tons of high-grade silicate cement, making it the largest single cement plant in China in terms of capacity. In line with the concept of circular economy and environmental protection, the company is also constructing a 2.5MW low-temperature waste heat power generation system and a dedicated wharf on the Yangtze River for comprehensive resource utilization. This project marks another major industrial project in the Chongqing area following Dongfang Hope Group’s investments in Fuling, where over 3 billion yuan was invested in building a 900,000-ton PTA project, and in Wansheng, where over 3 billion yuan was invested in projects producing 200,000 tons of methanol and 300,000 tons of acetic acid. Once completed, it will provide an important economic channel for the deep processing of fly ash generated by the Fuling and Wansheng projects, and the cement products produced will provide great support and guarantee for the reconstruction work in the disaster-stricken areas of Sichuan. The start of this project signifies the launch of another industrial giant by Dongfang Hope Group after agriculture, aluminum, and chemical industry, and it will play a significant role in promoting the development of the circular industrial chain economy in Chongqing and western regions, developing western resources, driving local economic development, and promoting economic prosperity in Chongqing and the Three Gorges Reservoir Area.

The company adheres to the development philosophy of “pursuing rationalization in every detail, striving to create relative advantages for the enterprise, giving a little more and contributing a little more to consumers”, and insists on core values of “integrity, righteousness, and justice”. It follows the talent concept of “both virtue and talent, with virtue first; suitable and adaptable for enterprise development”, requiring cadres to be the “role models, teachers, and coaches” of employees, helping employees grow and develop, so that employees’ gains are obtained through efforts, and their abilities are enhanced through work. Ultimately, cadres and employees become “role models, teachers, and coaches” for the general public, contributing to the improvement of the comprehensive quality of the nation and promoting social progress and development. We will provide a fair and just competitive environment for every employee dedicated to the company’s development and strive to build a platform for them to display their talents. Dongfang Hope Chongqing Cement Co., Ltd. will open an ever-present door of success for aspiring individuals around the world! “With the rising sun in the East, hope for China”, the rapidly developing Dongfang Hope Group is your ideal choice. We eagerly look forward to your pride in Dongfang Hope, and Dongfang Hope is more wonderful with you!

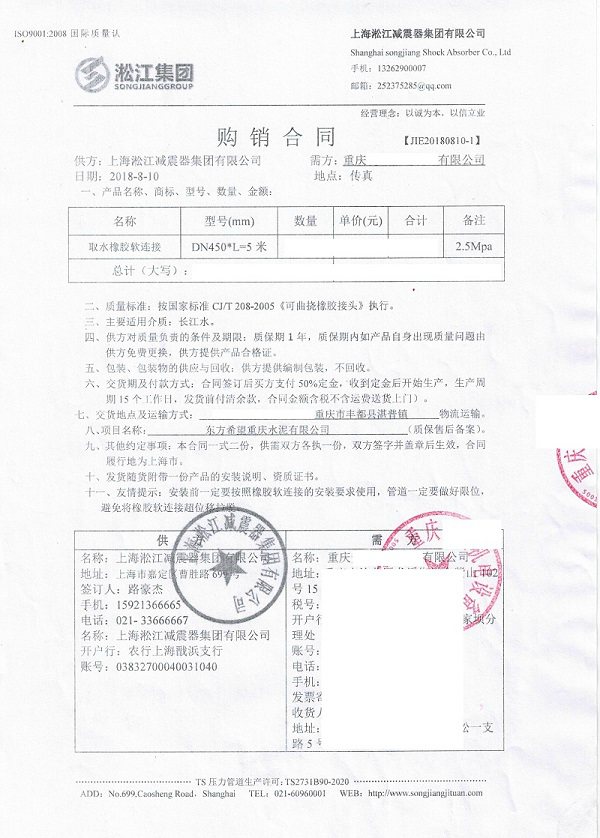

Contract Introduction for Single Rubber Expansion Joints at Dongfang Hope Chongqing Cement Plant:

Below is a scan of the authentic contract. Please do not modify or reprint. This contract serves as proof of supply. Thank you for your cooperation.

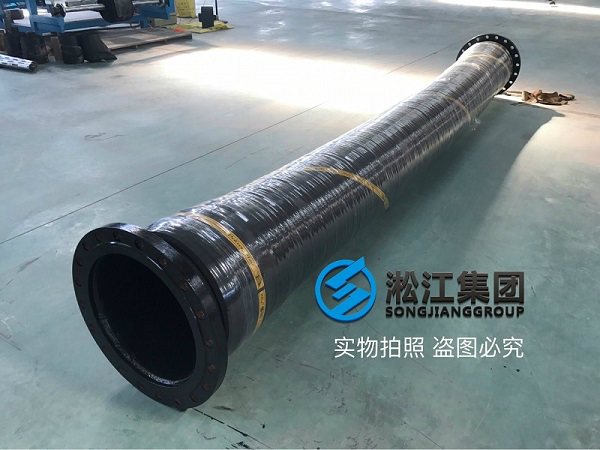

Introduction to Single Rubber Expansion Joints for Yangtze River Water Intake at Dongfang Hope Chongqing Cement Plant:

Technical Conditions:

A. On-site Mining Conditions:

Floating and Friction: Floating bridges rise and fall with the Yangtze River’s water level, causing the pipelines laid on them to stretch, bend, and come into contact with friction points.

Vertical Movement: The Yangtze River’s water level ranges from 145 meters to 175 meters, with a maximum rise and fall range of 30 meters.

Outdoor Environment: As the rubber expansion joints are installed outdoors, they are exposed to sunlight, temperature variations, wind, and sand, with significant environmental impacts. The Yangtze River area experiences strong natural winds, which can cause weathering damage to the rubber hoses.

Temperature: The highest temperature throughout the year is 40°C, with abundant sunlight and long exposure periods from May to October; the lowest temperature is 0°C, which can cause damage to the rubber hoses, such as frostbite.

Swinging: Frequent movement of large loading machinery on cargo ships, berthing of cargo ships, and wind and waves can cause the cargo ships to sway and the pipelines to swing.

B. Parameter Requirements:

Diameter: DN450

Pressure: 2.5 MPa

Length: 5 meters

Service Life: 8-10 years

Accessories: Bolts, nuts, flat washers, rubber pads

C. Manufacturing Requirements:

Mainly composed of inner and outer rubber layers, fabric layers (no less than 20 layers), and steel wire rings (diameter 6mm) forming a tubular rubber structure.

Both ends of the flange (one end being a movable flange) need to be welded to carbon steel pipes (thickness not less than 6mm) and vulcanized with rubber, with a length greater than 500mm.

D. Manufacturing and Inspection Standards:

The products provided by the bidder must meet the on-site conditions of Party A, as specified in Clause 2, and undergo a hydraulic pressure test before leaving the factory. A hydraulic pressure test report must be provided to Party A, and a hydraulic pressure test must be conducted on-site after the products arrive.

Party B shall provide a “Safety and Maintenance Instructions Manual”.

The product’s appearance quality must be aesthetically pleasing.

E. Warranty Terms:

The warranty period for the equipment supplied by Party B shall be one year from the date of commissioning.

In case of quality problems with the product during the warranty period, Party B must provide free maintenance. Party B must arrive at the product installation site within 48 hours after receiving notification from Party A.

Related links:[EPDM] Expansion joint related welding neck flange “With Independent Laboratory”