The official website of Shanghai Songjiang vibration absorber Group Co., Ltd. introduces to you: contract information of SUS304 EPDM flanged rubber bellows in Harbin polar Pavilion project, Songjiang group provides high-quality rubber expansion joints for many polar worlds with a product warranty of 5 years. We will contribute to more polar pavilions.

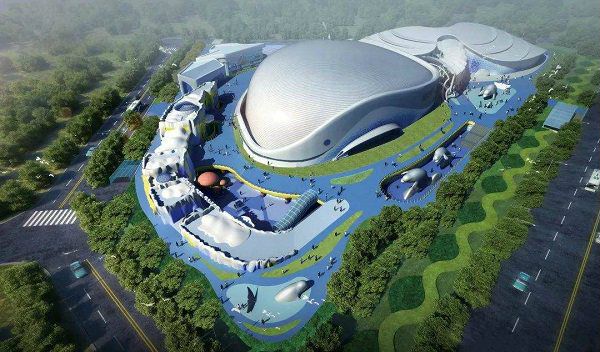

Introduction to Harbin polar Pavilion project

On the morning of April 29, 2019, the second phase of Harbin polar Pavilion project started to lay the foundation. The project is expected to invest 800 million yuan to create two international level polar animal theme shows, build new theme scenic spots such as “whale world”, “polar fantasy show”, “polar bear Pavilion”, “Antarctic enterprise island” and “whale strange business street”, integrate with phase I project, and build China’s first “four seasons ice and snow” polar theme park with polar animal show as the core, becoming the “polar place in the heart” of tourists, Build a model of industrial projects integrating culture and tourism.

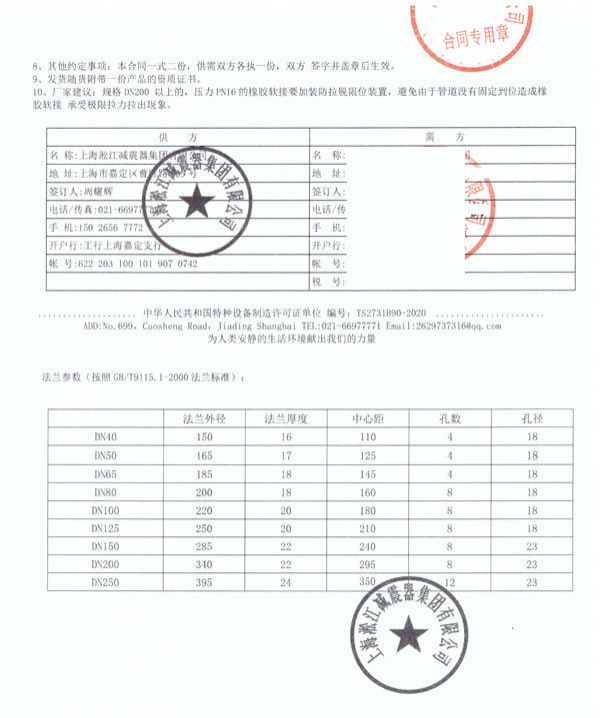

Application case and contract introduction of SUS304 EPDM flanged rubber bellows in Harbin polar Pavilion project

Application case of SUS304 EPDM flanged rubber bellows in Harbin polar Pavilion project

SUS304 EPDM flanged rubber bellows mainly uses the unique properties of rubber, such as high elasticity, high air tightness, medium resistance and radiation resistance. It is made of polyester cord fabric with high strength and strong cold and heat stability. It is cross-linked by high-pressure and high-temperature molding. It has high internal density, can withstand high pressure, excellent elastic deformation effect, product structure design, high end face arc, long curve and large multiple displacement functions, It is especially used in places with complex geological conditions, large settlement range and frequent changes in cold and heat during pipeline movement, which are easy to cause pipeline damage.

Related links: [SUS] Expansion joint related welding neck flange